Binding Services

HF Group offers a full range of library binding products and services.

![]() Click + to read about each of our service offerings.

Click + to read about each of our service offerings.

General Specifications

All periodicals receive the highest quality, preservationally sound workmanship. Materials are the best quality available including 100% internally plasticized copolymer polyvinyl acetate adhesives and acid-free and buffered endpapers.

Items are bound as sent with covers and advertisements left in place with issue sequence being spot-checked for accuracy.

Materials may range in size up to 12″ in height and 2″ in thickness. Oversize volumes, or volumes with different size issues, those requiring pockets, hand trimming or excessive mending or special handling may incur extra charges.

Proper Text Block Consolidation

All periodicals that are published in signatures will be sewn-through-the-fold to preserve the entire inner margin and to provide the best openability and photocopy ability.

Periodicals published with individual leaves will be double fan adhesive bound if the paper quality, text block size and weight will allow.

If the paper is glossy and inner margins are at least 5/8″, the volume will be oversewn.

Those few volumes with mixed publications (part signatures and part individual leaves) will receive special care. Either the signatures will be carefully split, rather than cut off, to preserve inner margins (page attachment will follow the previous guidelines) or the volumes will be sewn-through-the-fold with the individual leaves attached by hand sewing or oversewing.

Flex hinge endpaper is used on all oversews and the folded single folio endpaper is used on all double fan adhesive volumes. A folio endsheet is used for sew-through-the-fold volumes.

Preservation Principles

Outside margins are examined carefully to identify those volumes that have narrow margins and must be left untrimmed. Volumes that are left untrimmed will be jogged to the bottom so that the outside margins are as even and neat as possible. Leaving the margins untrimmed is an extra step and not a production shortcut.

Material used for lining the spine is top-grade, woven cotton that adds strength and durability to the binding.

Cover Making and Lettering

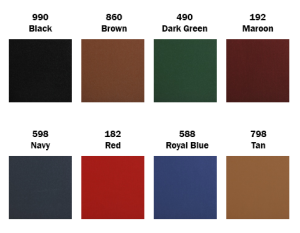

Covers are selected from an array of eight colors. The material is Library Summit™, an embossed latex-saturated cellulose/nylon blend with an aqueous acrylic coating, which has excellent internal strength, durability, and flexibility.

Lettering colors are white, gold and black. The number of lines of lettering on the spine is limited only by the space available.

Lettering is formatted using sophisticated computer applications that are integrated with state-of-the-art lettering equipment.

Case Making and Case Attachment

Cases are made in order to provide superior attachment of the textblock to the case. Volumes in excess of 2″ in thickness may be bound “flush-to-the-bottom” of the case. No bookbinding structure today can support a heavy textblock in mid-air. Flush-bottom binding allows the text block to rest on the shelf and hold its original shape.

Internally plasticized copolymer polyvinyl acetate adhesives are used in both the case making and the casing-in operations. This is very important for proper adhesion of the joint and increases strength, flexibility and longevity.

General Specifications

All standard monographs are carefully evaluated and properly treated in a preservationally sound manner. Each volume is individually inspected to determine the following:

- The proper textblock consolidation method that should be used

- Whether the outer margins will be trimmed

- If the original page attachment method can be salvaged

Standard hard cover monographs are bound as received and may range in size up to 12″ in height and 2″ in thickness. Binding of oversize volumes, or volumes with different size issues, those requiring pockets, hand trimming or excessive mending or special handling may incur extra charges.

Text Block Consolidation

When the original binding is not intact, monographs are rebound with an internally plasticized copolymer polyvinyl acetate adhesive applied using the double fan adhesive method.

Recase

If the original sewing is intact, the old adhesive and spine reinforcement lining is removed. New endpapers are hinged or sewn on and the textblock is left untrimmed.

If the first or last signatures of the book are broken, but the remainder of the textblock is sound, the endpapers and the sections are attached by stitching them by hand. These are also left untrimmed and only the endpapers are trimmed to fit the textblock.

All recase standard monographs that were originally rounded and backed will retain that shape. We will reshape the spine by hand and, if the paper will allow, we will touch up shoulders. Recase monographs may incur additional charges.

Cover Making and Lettering

Covers are selected from an array of eight colors. The material is Library Summit™, an embossed latex-saturated cellulose/nylon blend with an aqueous acrylic coating, which has excellent internal strength, durability, and flexibility.

Lettering may be white, gold or black. The number of lines of lettering on the spine is limited only by the space available. Lettering is formatted using sophisticated computer applications that are integrated with state-of-the-art lettering equipment. Automation and efficiency limit the choices of lettering to one style and three sizes of type. Other sizes and styles are available for a custom lettering charge.

Custom Services Art books, music books, or heavy reference books – published originally in sections – can be taken apart by hand and resewn-through-the-folds. This process is very time consuming, requires great care and skill, and is subject to extra costs. This will be done only with specific instructions from the library.

Monographs bound to match a sample, requiring specific color selection or lettering arrangement, or those requiring rub retention may be invoiced at a higher rate.

An Alternative to Traditional Standard Monograph Binding

For items that are not usually bound as standard monographs – typically soft cover materials – we offer a number of alternative binding options. While these are all high-quality products, the ANSI/NISO/LBI Standard for Library Binding does not apply to non-standard monograph binding.

Text Block Consolidation

The spines of non-standard monographs that have been bound with hot-melt adhesive by the publisher will have their spines removed and pages will be reattached by double fan adhesive binding using an internally-plasticized copolymer polyvinyl acetate adhesive. The spine lining is a strong, woven, cotton cloth that provides maximum strength and durability. Non-standard monographs that were originally sewn-through-the-fold will have this sewing preserved if it is still intact. New endpapers will be attached and the spine will be lined with cotton fabric. Overly worn or frayed volumes, or those volumes that may be part of the popular reading collection, may be shaved when practical.

Cloth

The covers of soft cover monographs are stiff and a potential failure point in binding so both the front and back covers are removed prior to page attachment. If the library chooses to retain the covers, an extra charge may be added for hinging and binding the covers into the textblock. Cover material is book cloth available in five colors that are selected randomly.

Lettering includes title and author and is usually stamped vertically on the spine. Call numbers, when requested, are also stamped vertically on the spine.

Pamphlets

Thin single signature and square spine material. Pamphlets are covered using our gray/white archival board with black poly-cotton c-cloth on the spine. Or Pamphlets can also be covered using gray archival board back and clear PETG front with blue poly-cotton c-cloth on the spine.

Dusties

Dusties are bound as received. The original dust jacket is trimmed, laminated and used in place of cloth for the cover.

Mylar

If the library chooses, the original soft cover can be removed, laminated and reused to construct a new hard cover preserving the original appearance of the soft cover book. Bind slips are not required for Mylar binding.

DigiCover

Using advanced photocopy techniques, the original cover is color-copied, laminated, and incorporated into a new cover.

CopiCover

Using advanced photocopy techniques, the original cover is color-copied on to ImagEase paper and is incorporated into a new cover.

NOTE: Not all products are available at all locations. Please contact your customer service representative for more information.

For Libraries

Our binderies are happy to bind pre-printed sets of theses and dissertations for libraries. Loose pages are double-fan adhesive bound in the order received. Binding and trim margin are checked. Spine stamping only is included in the basic price. Covers are made from your choice of eight colors. The material is Library Summit™, an embossed latex-saturated cellulose/nylon blend with an aqueous acrylic coating, which has excellent internal strength, durability, and flexibility. Lettering choices include white, black, and gold. Additional charges will be incurred for special requests such as front cover stamping, die stamping, or use of other cover material.

The following Library Summit cover colors are available:

An Ideal Microenvironment!

KASEBox provides an ideal microenvironment for your materials, protecting them from the effects of light, wear, impurities in the air, as well as variations in temperature and humidity. It is a high-quality and economical enclosure that is custom produced to fit each individual piece securely.

Each KASEBox enclosure is made of acid-free/lignin-free e-flute corrugated board that is buffered with calcium carbonate. The standard board is a clean-looking blue/gray color with strength ratings in excess of 200 lb. test.

Lettering is applied to the enclosure by plotting directly on the board, or a label can be applied.

Two Styles

KASEBox enclosures are available in two standard styles: clamshell and portfolio. Additionally, KASEBoxes are available in phase box, telescoping lid, and slipcase styles.

Your Materials Stay In The Library

One of the most attractive features of the KASEBox enclosure is that it is made from your measurements, not your materials. You will be supplied with instructions that will guide you through the simple process of measuring your materials. You simply send us the measurements, and we send you the finished box.

Electronic Ordering

Through our web site, we offer an application that you can download and use to enter measurements and submit orders electronically.

More Information...

For more product and ordering information, visit our archival boxes website: http://archival-boxes.com/products/kaseboxes/

Preservation

HF Group preserves current publications and archival material in bound volumes using library certified binding methods. We can also create custom storage boxes and scan material into digital formats. Whether you are a daily paper looking for digital archive support or a local publication hoping to store your area’s history we can help.

Methods

Newspapers measuring 17″ and under are bound using double fan adhesive binding. Newspapers over 17″ are sewn by hand. Both methods produce a durable volume with minimal loss to the gutter. The volume will then be cased into a hard cover made from F Grade buckram (15 colors available) with foil stamping (Black, White, or Gold) applied to the spine of the book.

Trimming

Newspapers can be trimmed smooth after being bound or left un-trimmed. Trimming will give each volume a smooth edge but can result in content being trimmed from the pages of the paper. Please indicate on your order form which method you would prefer, but Houchen Bindery Ltd can not be held responsible for trimming into content on the page if trimming was selected.

Preparing Your Papers

Store papers flat and unfolded, keeping them in the order of publication.

- Papers that have been folded for an extended time require special handling and preparation at the bindery before they can be bound and a fee will be charged for handling.

Remove any portions of the paper, like advertisements, you do not wish to have bound.

- These can be removed by the bindery for a fee. Indicate this on your order form.

The number of papers bound into one volume will vary based on the size and number of sections in the paper. A maximum thickness of 2″ is suggested per volume.

In addition to our tradition products, we provide binding services for a number of specialty items:

- Special Reports

- Minutes

- Legal Briefs

- Bulletins

- Pathology Reports

- Music Books/Scores

Materials are bound as received. All margins are carefully checked before trimming; volumes are not trimmed if there is insufficient margin. Generally, cases can be constructed of a wide variety of materials in many colors.

Special Reports

Due to the uniqueness of these products, significant special handling is required. Spine or front cover lettering is done according to customer instructions. Company logos can also be stamped if camera-ready artwork is sent. Cases are made to accommodate tabs if necessary.

Minutes

All volumes are carefully inspected and all staples are removed. Spine or front cover lettering is done according to customer instructions.

Legal Briefs

All tabbed volumes are left untrimmed. Spine or front cover lettering is done according to customer instructions. Firm and client logos can also be stamped if camera-ready artwork is sent. Cases can accommodate tabs if necessary.

Bulletins

All volumes are carefully inspected and staples are removed if necessary. Spine or front cover lettering is done according to customer instructions.

Pathology Reports

Many times this type of material requires a great deal of special handling because of the uniqueness of the paper. All volumes are carefully inspected and staples are removed prior to binding. Spine of front cover lettering is done according to customer specifications.

Newspapers

Many times this type of material requires a great deal of special handling because of the uniqueness of the paper and variation in size. All items are carefully inspected and staples are removed if appropriate Spine or front cover lettering is done according to customer instructions.

Music Books and Scores

A wide variety of cloth and paper pocket materials are used to meet customer requests and specifications. Spine or front cover lettering is done according to customer instructions.

NOTE: Not all products are available at all locations. Please contact your customer service representative for more information.

Library Assistance Services allow libraries to reduce the amount of staff time needed to process volumes both before and after binding.

Box and Bind services include the various steps that are performed before volumes are sent for binding or during the binding process.

Shelf Help shelf-ready services include steps that are typically performed after the bound volumes are returned from the bindery.

Box and Bind: Bindery Preparation Services

Box and Bind services include the following:

Bindery Preparation for Monographs

Monographs are boxed and sent with the bindery shipment. Lettering information is entered in the bindery, eliminating the need to prepare binding tickets in advance.

Bindery Preparation for Journal Volumes

Journal issues are bundled together and packed at the library. The bindery will ensure that issues are in the correct order, and will use your existing journal database to prepare the volumes for binding.

Treatment Decision Making and Bindery Preparation

The library packs all materials needing preservation treatment. The bindery will sort the materials and, based on a profile completed by the library, will assign the appropriate treatment for the item, such as binding, conservation treatment or preservation photocopying.

Within days of receiving the shipment, we will sort the materials and send a detailed report to the library documenting the selected treatment for each volume. After receiving confirmation from the library, the treatment process will begin.

Copying Cover, Pastedown or Dust Jacket Information

To preserve information on the cover, pastedown or dust jacket, the bindery will photocopy this information and bind the copied pages into the volume. Both bitonal and color photocopies are available.

Color Copy Original Cover

To preserve the look of original publisher binding, the bindery will make a color copy of the original cover and use that to produce a Clear Cover binding.

Tattle Tapes

The bindery will insert Tattle Tapes during the binding process.

Shelf Help: Shelf-ready Services

Edge Stamping

The bindery will stamp up to two edges of each bound volume.

Pre-sorted Packing

The bindery will sort bound volumes by type, location, or both and will pack them accordingly. This service eliminates the need to sort the shipment after it is received in the library.

Additional Marking or Labeling

The placement of additional marking or labeling, such as “Do Not Circulate” stickers, can be done at the bindery after a volume is bound.

Bookplates

Bookplates can be placed, as designated, into bound volumes.

Item-specific Bookplates

Special recognition bookplates, such as those commemorating donors, can be placed, as designated, into bound volumes.

Date Due Slips

The bindery will supply and place Date Due Slips in bound volumes.

Report Preparation

The bindery can provide a wide variety of reports to meet the needs of your library. If your library subscribes to two or more Box and Bind services, or two or more Shelf Help services, report preparation services are provided free of charge.

NOTE: Not all products are available at all locations. Please contact your customer service representative for more information.

About ABLE

ABLE is a binding automation solution that helps manage the flow of materials between the library and the bindery. ABLE™ is a third-generation system that was developed specifically for use on the internet.

Web Start

There are two interface options for ABLE: Webstart for Oracle Java (license required) or Webstart for OpenJDK Java (64-bit systems only). The attached documents provide the instructions for installing whichever you wish to use.

If you would like to start using ABLE, please contact our technical support team at support@hfgroup.com and we will be glad to help you.

Commitment to Service

At HF Group, we pride ourselves in delivering complete shipments... on time, every time! This simplifies the management of your binding operation and puts materials back in your patrons' hands quickly. We are also firmly committed to providing you with timely and accurate invoices. This allows you to complete the processing for your binding quickly and efficiently. We refuse to sacrifice any one of these essential goals at the expense of another. As a result, libraries can expect our dedication to outstanding service.

Commitment to Quality

All volumes receive the highest quality workmanship and full preservation treatment. Materials are the best quality available including 100% internally plasticized copolymer polyvinyl acetate adhesives and acid-free and buffered endpapers. Our page attachment decision tree ensures that the proper textblock consolidation method is applied to all library binding products. Throughout the binding process, we strive to provide our customers with the best possible products and services.